The old watchmaker sat at his bench, a loupe pressed against his eye, hands steady as he worked on a movement so small, yet so significant. His fingers, calloused from years of meticulous labor, guided a fine file along the edge of a tiny bridge, smoothing it into a gleaming, angled surface. To an untrained eye, this might seem like an unnecessary detail, a flourish that no one would ever notice. But to him, and to those who understood the art of fine watchmaking, this was where the true soul of a timepiece lived.

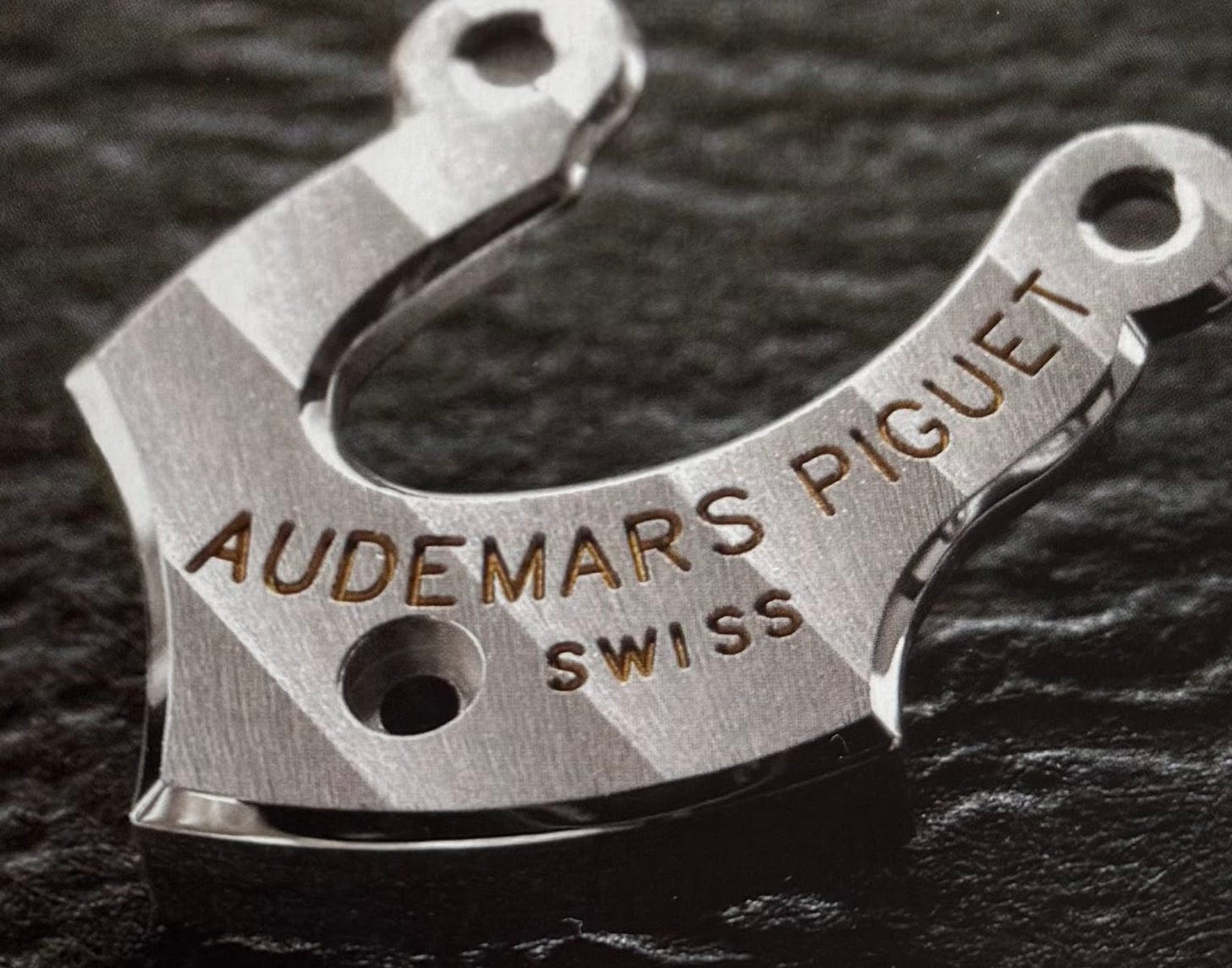

In the world of haute horology, craftsmanship is everything. A watch is not just an instrument that marks the passing of hours—it is a work of art, a legacy of human ingenuity and patience. Within this world, a select group of artisans dedicate their lives to the perfection of finishing techniques, ensuring that even the smallest details are executed with precision. Among these techniques, one of the most revered is beveling, or anglage, a method that transforms raw metal components into shimmering, polished surfaces.

The practice of beveling dates back centuries, born from an obsession with perfection. In 18th-century Geneva, watchmakers would refine even the hidden parts of a movement, believing that true artistry should extend beyond what was visible. To them, a movement had to be just as beautiful beneath the dial as it was on its surface. This philosophy endures to this day—only now, the best collectors and connoisseurs know where to look for such details. A finely beveled edge is a signature of excellence, a mark of a watchmaker who refuses to cut corners, quite literally.

To achieve this level of refinement, the watchmaker relies on a set of carefully chosen tools. A series of fine files, small and precise, shape the initial bevel. Ceramic stones smooth the surface, preparing it for the final and most labor-intensive step: polishing. This is where patience becomes paramount. A wooden peg coated in diamantine powder is used to bring the edge to a mirror finish, ensuring that light glides effortlessly along its surface. The process is slow, requiring unwavering attention, but the result is a beveled edge so perfect that it seems to glow from within.

Every beveled edge must meet strict, almost sacred standards. The angle must be consistent, typically at 45 degrees. The transition between the beveled edge and the flat surface must be sharp yet smooth, crisp but not harsh. Any imperfection, no matter how minor, is unacceptable. In the hands of a master, a bevel is not just an aesthetic detail—it is a testament to skill and dedication.

Of course, technology has made its way into this world, bringing with it machines capable of mass-producing bevels. These machine-assisted bevels are neat, efficient, and consistent, but they lack the warmth, the character of a hand-finished piece. There is an almost intangible quality to a hand-polished bevel, a depth that machines cannot replicate. The edges seem to dance with light, revealing the presence of human touch, the mark of an artisan who devoted hours to perfection. Those who truly appreciate fine watchmaking can tell the difference—one is flawless in a way that feels clinical, while the other carries the soul of its maker.

The beauty of a beveled edge is not just in its appearance but also in its function. Those sharp, raw edges left untouched could lead to stress fractures over time, weakening the integrity of the movement. By smoothing and polishing these edges, the watchmaker ensures longevity, reducing wear and friction between components. This is why the finest timepieces are not just beautiful; they are built to endure.

Many of the world’s most renowned watchmakers have made beveling their signature. The independent master Kari Voutilainen, for example, devotes countless hours to hand-finishing every bevel in his movements, ensuring that each one meets the highest standards. Philippe Dufour, often considered the godfather of hand-finishing, has set a benchmark with his legendary Simplicity model, where the bevels shine with a depth and clarity that machines will never achieve. Audemars Piguet, Patek Philippe, and Jaeger-LeCoultre all incorporate beveling into their movements, sometimes in ways that are subtle, sometimes in ways that are bold, but always with an understanding that it is these hidden details that elevate a watch to greatness.

Even as watchmaking evolves, embracing new materials and methods, beveling remains one of the last strongholds of traditional craftsmanship. The future may bring new finishing techniques, but a hand-polished bevel will always be a sign of dedication, of mastery, of something deeply human. It is a quiet mark of excellence, an unspoken statement that this watch was made not just to keep time, but to honor it.

The old watchmaker lifts his loupe and inspects his work. The bevel catches the light, glowing like a perfectly cut gemstone. He nods in quiet satisfaction, knowing that while most will never see this hidden detail, those who do will understand. And that, after all, is the true essence of craftsmanship—creating something exceptional, even when no one is watching.

*****